MECH 402 Design Capstone Project

A prosthetic shower leg designed to be compact for travel, easy/available to manufacture, as well as being cost effective. This was my senior capstone project, where I worked collaboratively to create this collapsible prosthetic shower leg, 3D printed from Nylon 12 Carbon Fiber filament. The design incorporated a button-locking pylon that allowed for adjustments in height. The design of the foot introduced a curved feature to replace the need of an ankle joint.

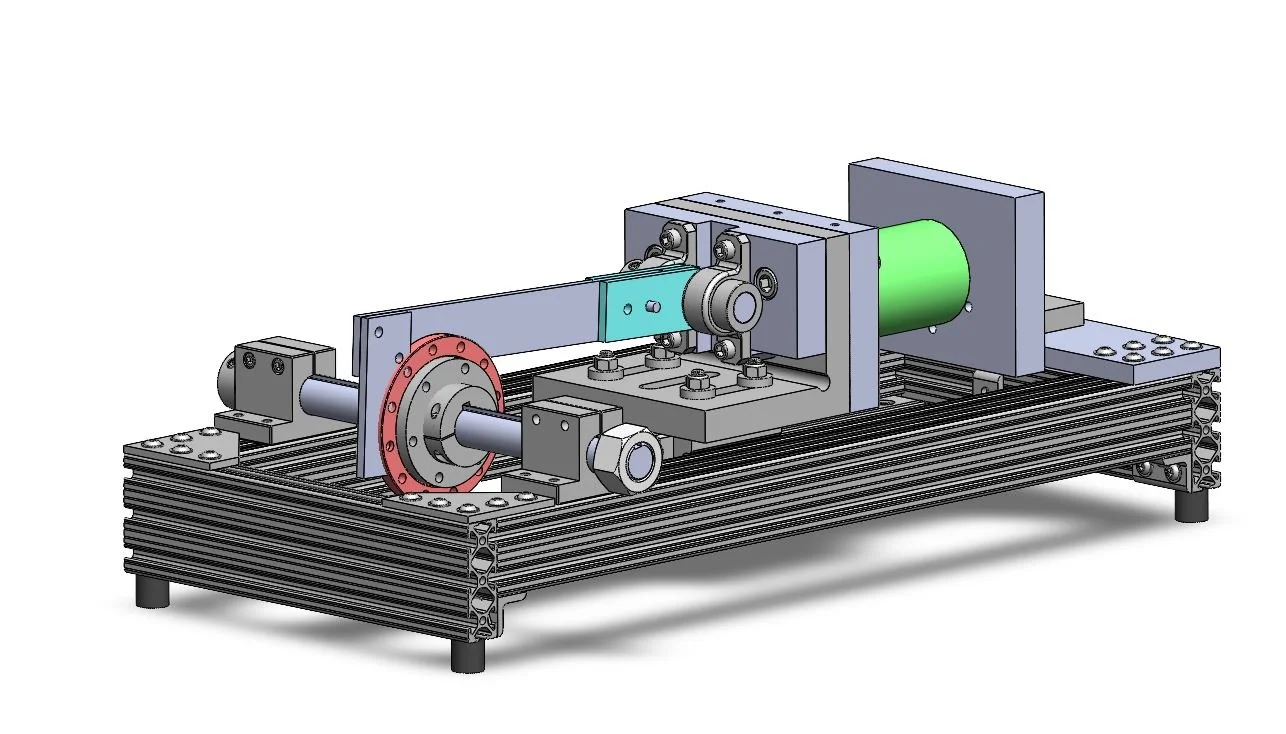

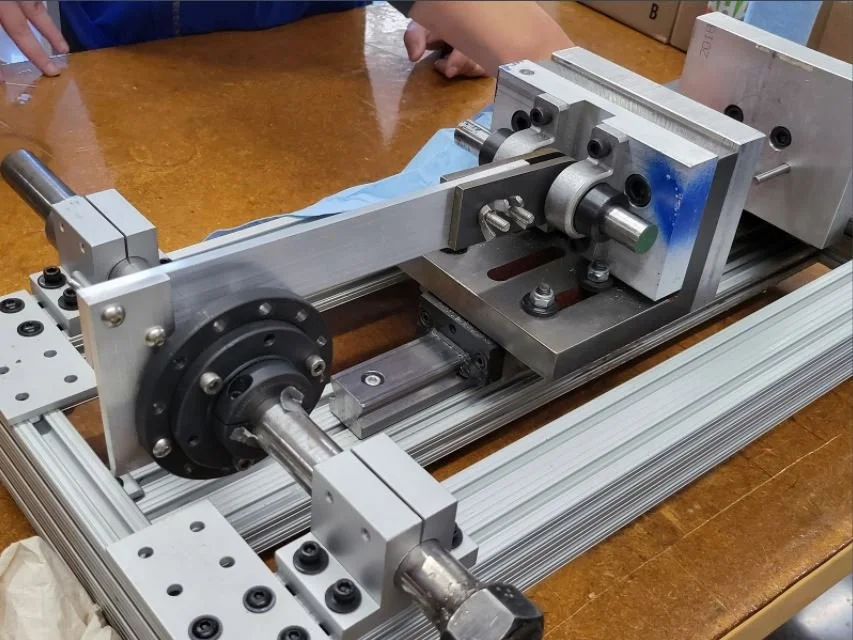

Mech 410 Design and Manufacturing Final Project

A linkage was designed to transfer rotational into translational force in order to crush an empty can, but have a shear pin fail before a full soda can could be crushed. The design was specialized to require almost zero input force to crush the empty can, while still having the pin fail with the full soda can.

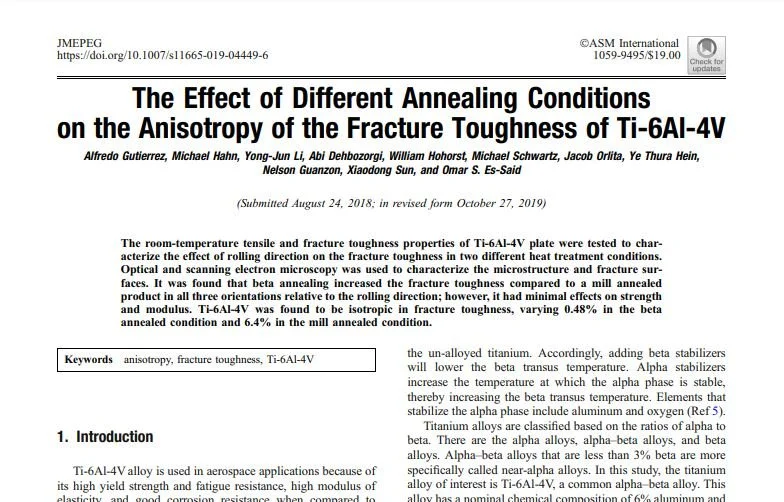

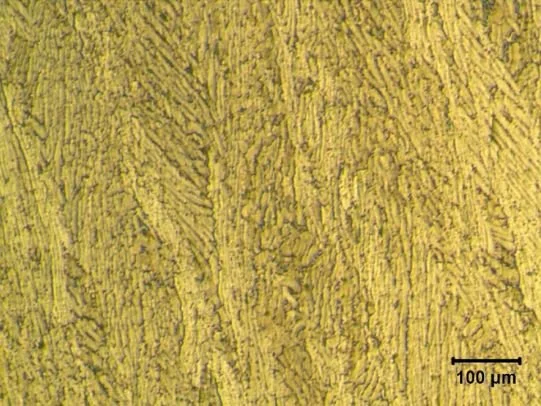

ASM International Publication

A research paper that studied the effects of polishing direction on the fracture toughness in two different heat treatment conditions for the titanium alloy Ti-6Al-4V.

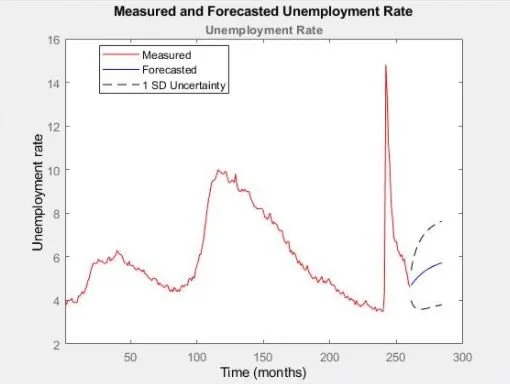

MATH 355 Methods Applied Math Final Project

A MATLAB program that takes any given historical time versus quantity data, and predicts future trend. This program was applied initially to evaluate unemployment. However, this program can be applied to any models like COVID-19 infection rates or even stock behavior over time.

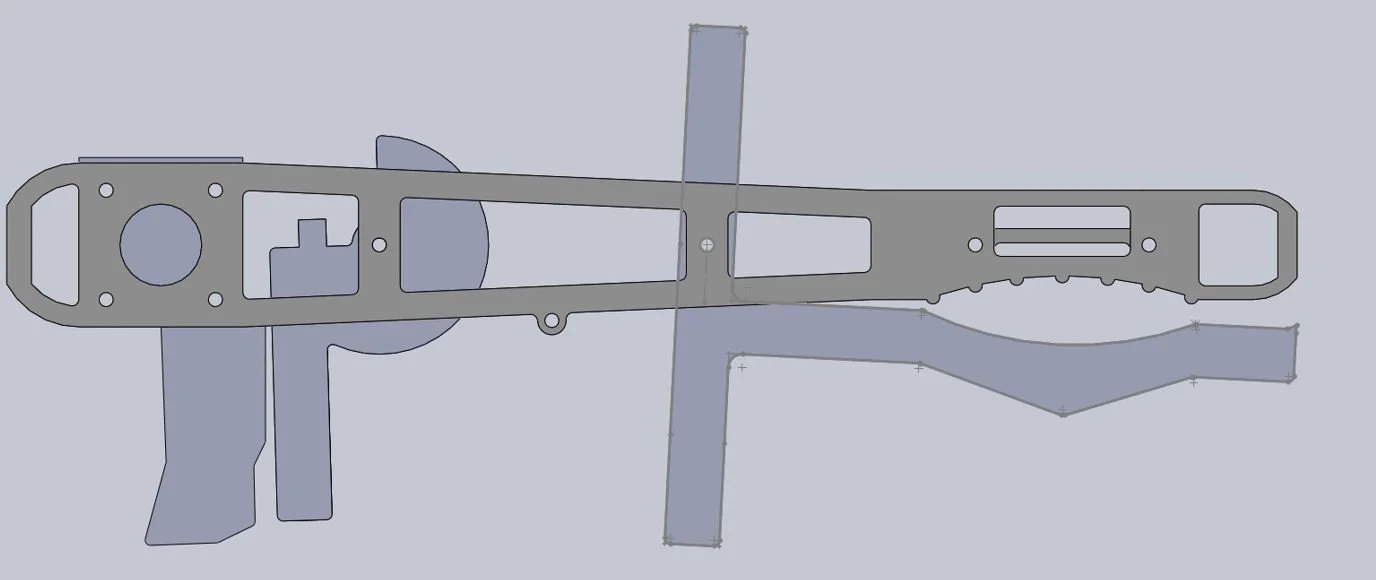

MECH 410 Design and Manufacturing Project

A soda can grabber where the components were manufactured using a laser cutter.